- Details

- Category: Articles

Wind power's portrayal as a 100% clean source of renewable energy bodes well for those seeking a power source with little environmental impact. Nevertheless, to stay true to this green promise, we mustn't lose sight of the carbon footprint laid down prior to the generation of electricity. Composite materials, acknowledged as an enabler of the green promise, can contribute greatly to this footprint. In recognition of this reality, manufacturers' have turned from open mould processing to closed mould vacuum infusion processing.

Wind power's portrayal as a 100% clean source of renewable energy bodes well for those seeking a power source with little environmental impact. Nevertheless, to stay true to this green promise, we mustn't lose sight of the carbon footprint laid down prior to the generation of electricity. Composite materials, acknowledged as an enabler of the green promise, can contribute greatly to this footprint. In recognition of this reality, manufacturers' have turned from open mould processing to closed mould vacuum infusion processing.By Patrick Mack, Chief Technologist, Polynova Composites, USA

- Details

- Category: Articles

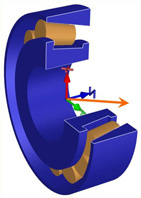

This article details the effect of including accurate stiffness models of rolling element bearings in the dynamic simulation of planetary wind turbine gearboxes and discusses the frequently neglected subject of bearings' contribution to the dynamic behaviour of turbine gearboxes.

This article details the effect of including accurate stiffness models of rolling element bearings in the dynamic simulation of planetary wind turbine gearboxes and discusses the frequently neglected subject of bearings' contribution to the dynamic behaviour of turbine gearboxes.By Richard Dorling, Romax Technology, UK

- Details

- Category: Articles

Floating, Autonomous, Environmentally Friendly and Efficient Desalination Unit

Global warming is an emerging threat to water availability and to the quality of life in isolated island communities in southern Europe. Isolated small islands in the Mediterranean region already experience the problem of scarce water sources during the dry summer period. Climate change is likely to further aggravate this situation in the coming years and therefore alternative water sources have to be investigated in these areas.

Global warming is an emerging threat to water availability and to the quality of life in isolated island communities in southern Europe. Isolated small islands in the Mediterranean region already experience the problem of scarce water sources during the dry summer period. Climate change is likely to further aggravate this situation in the coming years and therefore alternative water sources have to be investigated in these areas.

- Details

- Category: Articles

Jacket Substructures for the REpower 5M Wind Turbine

Support structures for offshore?application, especially in deeper waters, have?been identified by?many?sources as being able to make a?vital contribution to cost-effective?installations. Larger turbines, such as?the REpower 5M, demand significantly?stronger support structures than smaller turbines. REpower has gained experience?with jacket substructures for the?REpower 5M turbine?in recent projects. The?conclusions from this experience?will be?summarised in this article.

Support structures for offshore?application, especially in deeper waters, have?been identified by?many?sources as being able to make a?vital contribution to cost-effective?installations. Larger turbines, such as?the REpower 5M, demand significantly?stronger support structures than smaller turbines. REpower has gained experience?with jacket substructures for the?REpower 5M turbine?in recent projects. The?conclusions from this experience?will be?summarised in this article.

- Details

- Category: Articles

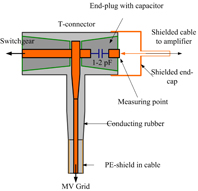

Designed for Documenting Fast Transients in High-Voltage Grids of Large Wind Farms

Although wind power development is still mainly based on land sites, a number of large offshore wind farms have been developed, and there are significant plans for further offshore wind power development, This development produces a need for accurate models of all main components in a wind farm because simulations are widely used to predict what happens in case of faults and switching operations in the grid. The result of simulations can always be questioned, and depends on the accuracy of the component models used in the simulation program. Validation of simulations with reliable measurements performed in a real large wind farm makes it possible to verify and improve the simulations and to give more reliable results. DELTA has built a system for measuring fast transients synchronously in three different locations on a wind farm.

Although wind power development is still mainly based on land sites, a number of large offshore wind farms have been developed, and there are significant plans for further offshore wind power development, This development produces a need for accurate models of all main components in a wind farm because simulations are widely used to predict what happens in case of faults and switching operations in the grid. The result of simulations can always be questioned, and depends on the accuracy of the component models used in the simulation program. Validation of simulations with reliable measurements performed in a real large wind farm makes it possible to verify and improve the simulations and to give more reliable results. DELTA has built a system for measuring fast transients synchronously in three different locations on a wind farm.By L.S. Christensen, P.E. Sørensen, T. Olsen, H.K. Nielsen and T. Sørensen, Denmark

- Details

- Category: Articles

The ever-increasing strain on the traditional exploration of natural resources to provide for the worldwide demand for energy is paving the way for the wind turbine sector. We are seeing a dramatic increase in the number and size of wind turbines, producing more watts by the day. Our sector has no shortage of technological needs, but no shortage of creative minds either. Nowadays, commercial and academic institutions are reaping the benefits of joint developments. One of many exciting new developments combines the hands-on knowledge of wind turbine mechanics with photosensor technology. This article details a reliable and accurate method for measuring angular velocities, rotor blade pitch angles and the perpendicularity of individual rotor blades using vision technology. The necessary technology is packaged into a commercial service for quick and cost-effective monitoring.

The ever-increasing strain on the traditional exploration of natural resources to provide for the worldwide demand for energy is paving the way for the wind turbine sector. We are seeing a dramatic increase in the number and size of wind turbines, producing more watts by the day. Our sector has no shortage of technological needs, but no shortage of creative minds either. Nowadays, commercial and academic institutions are reaping the benefits of joint developments. One of many exciting new developments combines the hands-on knowledge of wind turbine mechanics with photosensor technology. This article details a reliable and accurate method for measuring angular velocities, rotor blade pitch angles and the perpendicularity of individual rotor blades using vision technology. The necessary technology is packaged into a commercial service for quick and cost-effective monitoring.- Condition Monitoring for Wind Farms

- WindWing

- Virtual Simulation for Wind Turbine Engineering

- Load-Based Individual Blade Pitch Control Comes of Age

- Predictability and the Value of Wind Energy

- World's First Floating Wind Turbine

- Ready-to-Use Power

- PITCH System Cold Climate Version

- NewGen

- Challenges for Reliable Offshore Transformers

- Ampelmann Demonstrator Testing

- Flying for Wind Power

- Wind Turbine Aerodynamics Using CFD

- Steps Towards Lightweight Direct-Drive Generators

- Fracture Mechanics and Wind Turbine Blades

- A Needed Change in Orientation

- Is Damage Tolerance the Future?

- Introduction to 3D Landscape Tools

- The Physics Behind Wind Measurement

- Lightning Protection of Wind Turbines

- Monitoring and Condition Inspections of Wind Turbines

- The Technology of the 200-Metre Met Mast

- In Defence of the Wind

- Comprehensive Solution with Added Value

- Hull (Massachusetts, USA) Offshore Wind Project

- Wind Resource Measurement by Laser Anemometry

- Filling a Need for a New Tower Design

- Improvements in Wind Power Prediction

- What's Your Transformer Got in the Tank?

- Financing Wind in Eastern Europe